Share to

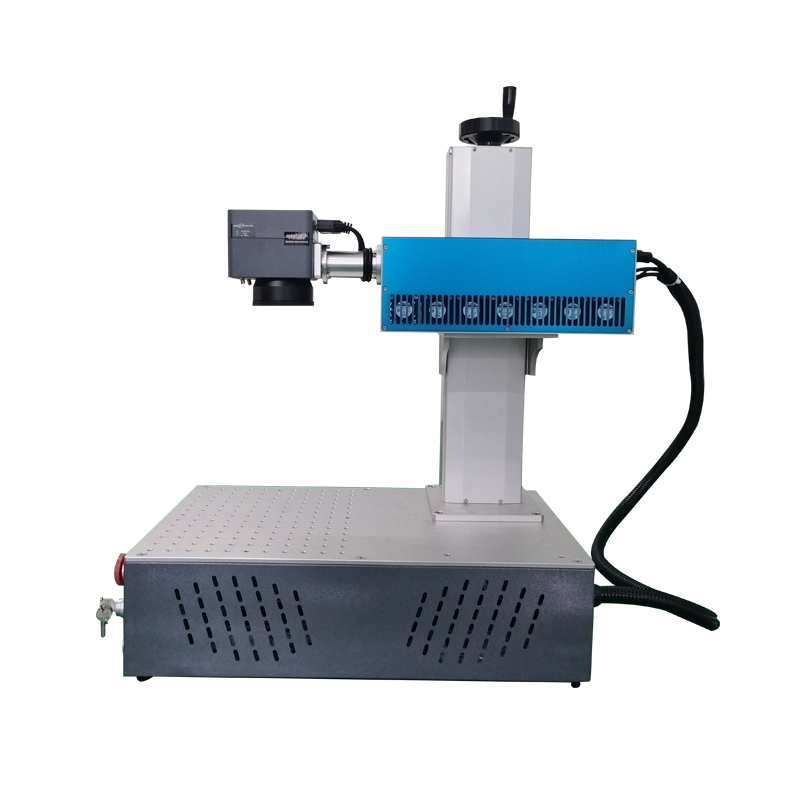

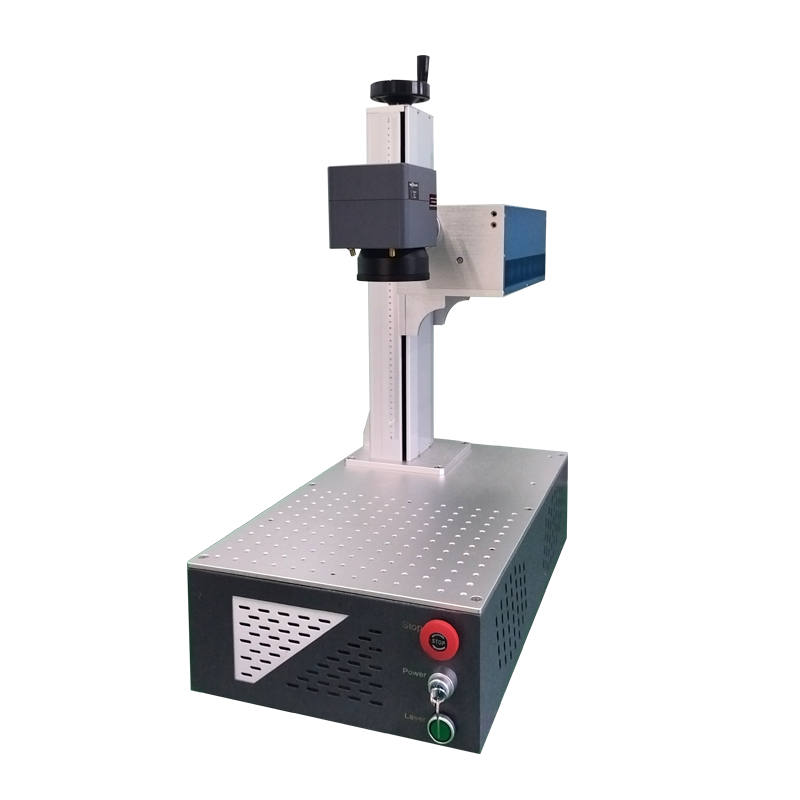

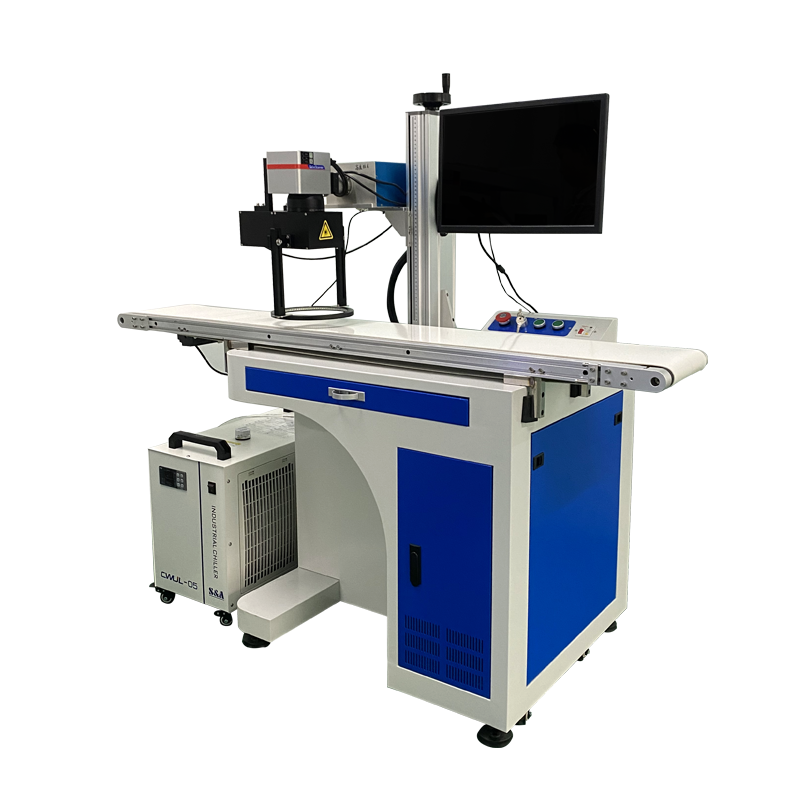

UV laser marking machine

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

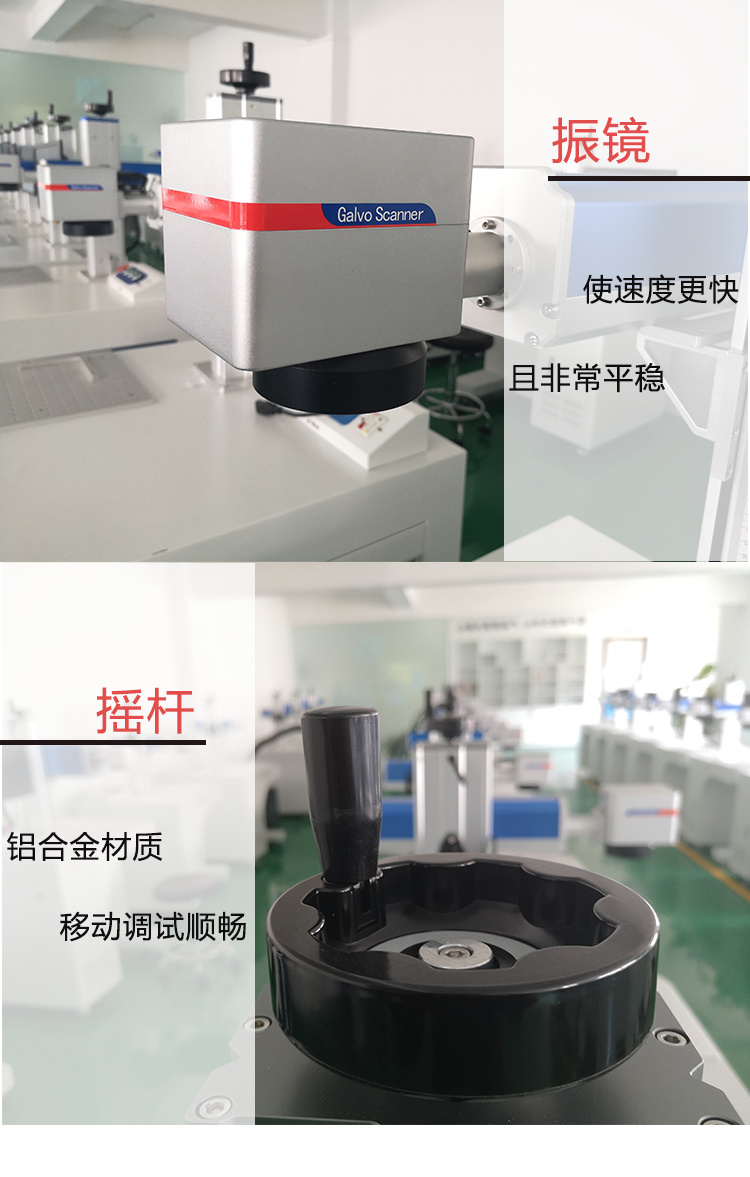

Principle of UV laser marking machine:

A cold working process is used. The process is called the "photoetching" effect. The "cold working" (ultraviolet) photons with very high load energy can break the chemical bonds in the material or the surrounding medium to make the material Non-thermal process damage occurs, the inner layer and nearby areas do not produce heating or thermal deformation, etc. The final processed material has smooth edges and extremely low carbonization, so the fineness and thermal influence are minimized. It is laser technology Great leap forward. The reaction mechanism of ultraviolet laser processing is realized by photochemical ablation, that is, relying on laser energy to break the bonds between atoms or molecules, so that they become small molecules and vaporize and evaporate. The focused spot is extremely small, and the processing heat-affected zone is minimal, so it can be used for ultra-fine marking and special material marking.

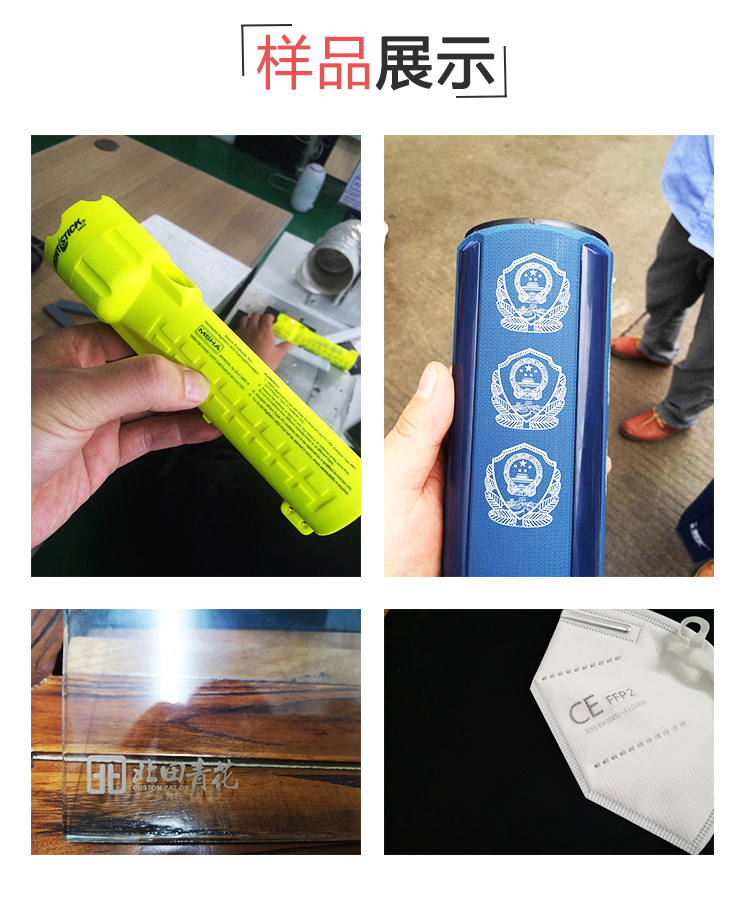

Use field:

Used in the ultra-fine processing high-end market, marking the surface of packaging bottles of iPhone, cosmetics, medicine, food and other polymer materials; marking and scribing on flexible PCB boards; processing of micro-holes and blind holes on silicon wafers; LCD liquid crystal glass , Glassware surface, metal surface coating, plastic buttons, electronic originals, gifts, communication equipment, building materials and many other fields.

UV laser marking machine

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note:We will contact you within one working day. Please pay attention to your email.